We create customized solutions with perfectly configured systems

Heesemann sanding machines serve a wide range of applications. Our mission is to provide the technology to meet your workpiece requirements and make your creative ideas and design concepts a reality. To fulfil our mission, we offer a wide range of units which our engineers can combine and adapt to meet every customer’s unique requirements:

Longitudinal sanding units

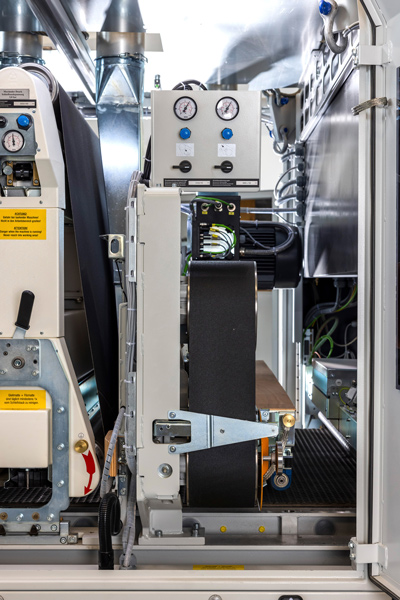

The longitudinal sanding units on the Heesemann surface sanding machines are equipped with the proven CSD® magnetic pressure beam system. Optionally, they can also be fitted with an eccentric bearing on the first bend pulley for precision calibration processes, with a pressure segment belt inside and with the even finer CSD® plus system.

Cross sanding unit

On wooden surfaces, the cross-sanding method is regarded worldwide as achieving the best sanding results. The workpieces are first sanded crosswise to the grain direction and then sanded in direction of the grain with one or more sanding units.

For removing glue protrusions, edge materials, tape, and other unevenness on the materials

- First sanding pass in the cross-sanding process

- High-gloss sanding with grits > P500

Orbital sanding unit OSR

When sanding frames and other workpieces with different grain directions, sanding crosswise to the grain direction cannot be avoided. The resulting sanding marks are especially apparent if dark stains are used. The Heesemann orbital sanding unit removes these marks.

The unit works utilises frequency controlled eccentric vibration with a large stroke. An additional segment belt press-on system moves between the pressure beam and a vibrating sanding belt crosswise to the feed direction.

In the process, the sanding marks created by the vibrating sanding belt are interrupted, creating harmonious sanding results without any disruptive sanding marks.

Roller units & knife rollers

The Heesemann contact roller units are available with both steel rollers and rubber-coated rollers with various Shore hardnesses. Both models are offered with different roll diameters.

Heesemann combo-units: brush units

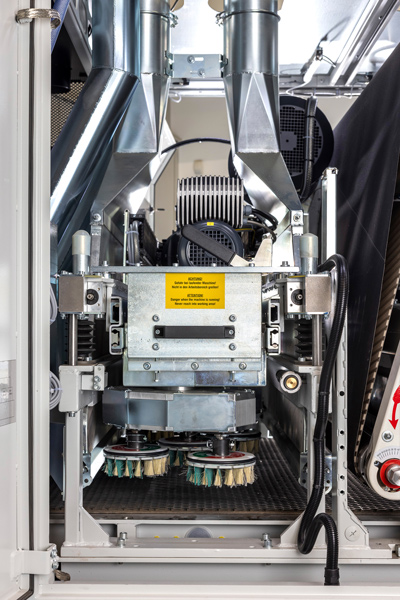

DB-S disc brush unit

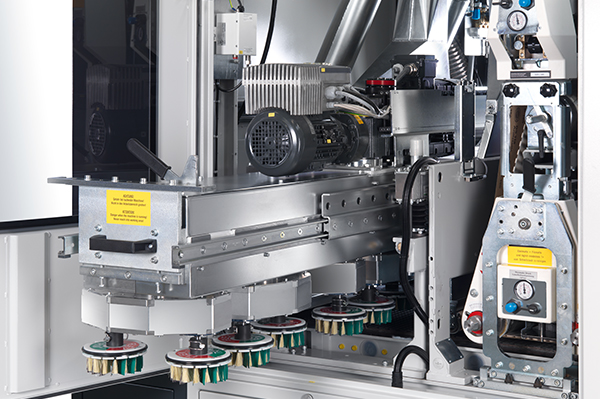

The DB-S unit brushes and lightly structures the workpiece surface. Five heads, each with two disc brushes, rotate lightly over the workpiece surface at high speed, eliminating unwanted sanding marks.

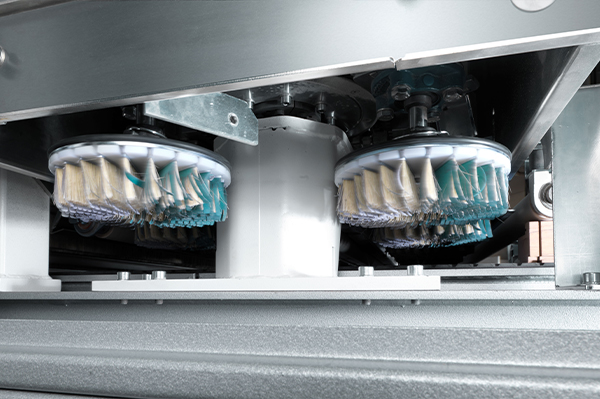

RUT disk brush unit

The RUT disk brush unit consists of 18 disk brushes. Their arrangement enable the sanding of contours with unmatched quality. All areas are evenly sanded in different directions.

The frequency-controlled drive system permits continuous regulation of the disk brush rotation speed and also their orbital velocity transversally to the feed direction.

The disk brushes can be equipped with two different abrasives at the same time. This enables the RUT unit to sand with different grits in and opposite to feed direction.

Using the quick changing device, the system can be switched from disk brushes with sanding fittings to structuring brushes, for example, in only a matter of moments.

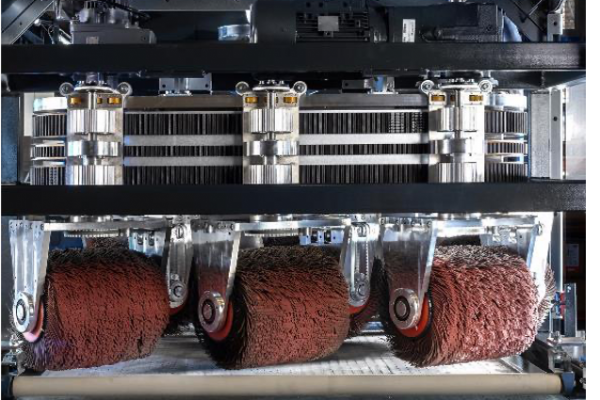

RUL

The RUL unit consists of 6 revolving satellites, each of which carries a 370 mm wide and 350 mm diameter brush sanding roller.

The orbital motion of the satellites in conjunction with their rotation around both their vertical and horizontal axes processes the workpieces with equal intensity from all directions. Something which no other brushing process on the market achieves.

These unique kinematics enable the use of pressure rollers in addition to the vacuum to hold the workpieceson the conveyor belt. This is a unique advantage, especially for long narrow parts and also for deformed workpieces.

Brush units

An array of brush units with different fittings for sanding and structuring are available for Heesemann sanding machines. The brush units can be mounted inclined to the feed direction or can feature oscillation.

Heesemann cleaning units: contactless

Ionisation rod

- One ionisation rod for the top and bottom sides of the workpiece are an integral feature of the Heesemann A 10 dedusting system.

- The ionisation significantly reduces the charge of static dust.

Rotating blaster

-

The rotating blaster serves to remove sanding dust from the surfaces, e.g. before coating.

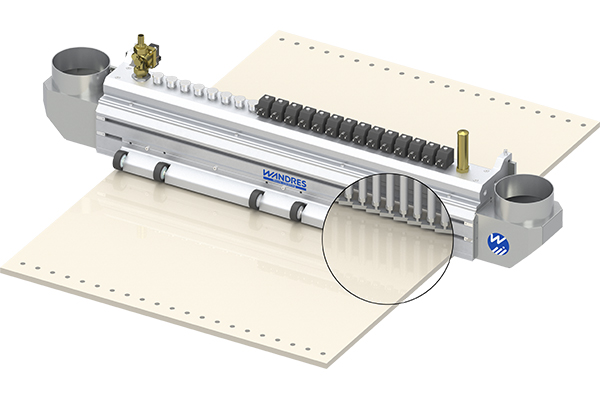

Wandres Tornado Channel

- Power nozzles blow the surface and into the bore holes vertically or at a slight angle.

- The particles rise and flow through the integrated vacuum channels to the extractor. The entire compressed-air flow transports the particles into the tornado channel.

Heesemann cleaning units: with contact

Cleaning brushes

-

Cleaning brushes for removing dust from the surface.

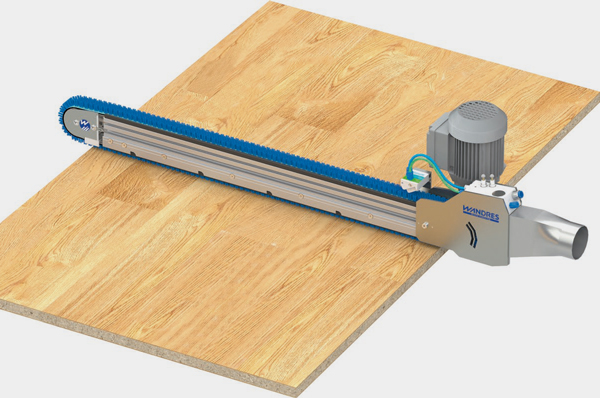

Wandres sword brushes

- Wandres sword brushes® always brush perpendicular to the transport direction of the surface being cleaned.

- The proven Ingromat® process guarantees gentle and reliable removal of dust and coarse particles from the surface.

- A thin liquid film is applied to the tips of the bristles. The capillary adhesion binds the particles removed to the bristles.

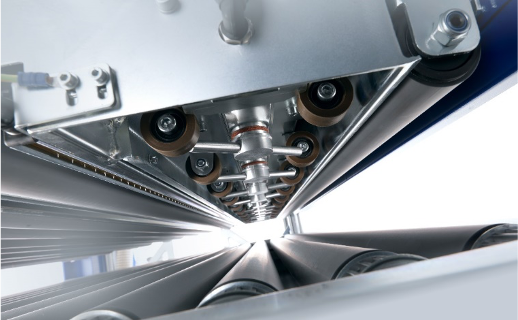

Heesemann surface effect units

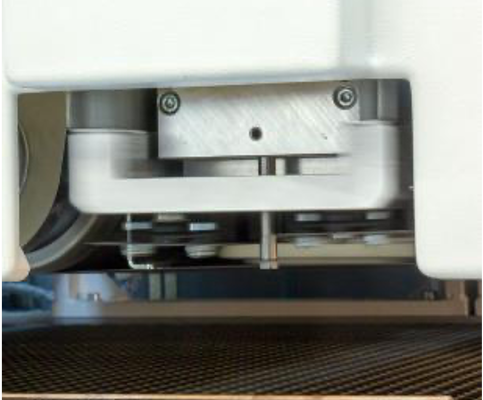

An example: the oscillating steel plate

As an option, the longitudinal sanding units in Heesemann sanding machines can be equipped with an oscillating steel plate. In combination with the Heesemann SSF Structured Surfaces Package and the Heesemann CSD® magnetic pressure beam planer, cut effects with a wavelike pattern across the surface can be created.