The success story of BRUNEX

Cooperation.

The municipality of Brunegg is a tranquil village in the canton of Aargau. Located in the north of Switzerland, it represents just about everything you would expect from such a place: scattered between the Reuss valley and the lower Bünztal, a few dozen houses blend into the lush green of the surrounding, lush forest. Above all of this, Brunegg Castle, which rises about 120 meters above the village at the top of Chestenberg, towers over the village. Brunegg does not only house a picturesque idyll. For more than 65 years, this remote location has been home to a company that can literally be called a hidden champion: The company Türenfabrik Brunegg AG is the leading door manufacturer for door systems made of wood in Switzerland. More than eight million Brunex door panels left the factory in Aargau during the course of the company’s history. As a partner to the specialized trade as well as carpenters, planners and architects, the company stands for innovation, quality, and appealing design.

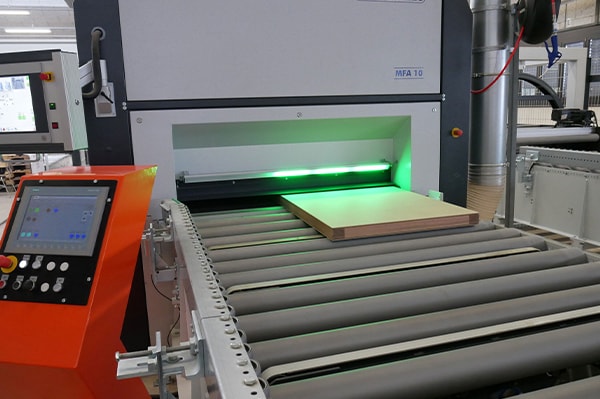

Previously, they worked there with a sanding machine from a manufacturer who had to stop production in mid-2016. As the service as well as the purchase of spare parts was endangered, Brunex was forced to find a new, reliable partner. The demands were clearly defined: The new sanding machine had to be integrated into the existing production line, be fully automatically controlled and be able to communicate with the other machines in the production chain.

The contact with Heesemann came about through HOMAG AG. And after the first exploratory talks, it quickly became clear that the needs of the Swiss door manufacturers fitted perfectly with the Westphalia offer. To ensure that the new machine lives up to the concrete ideas, the entire project was accompanied by the managing directors of the two companies.

A delegation headed by CEO Christoph Giese, Sales Manager Axel Sprenger and Construction Manager Klaus-Dieter Grave from Bad Oeynhausen traveled to Aargau to jointly define with the Brunex team of the Managing Director Mr. Martin Eisele which extensions and additional functions are needed. “The collaboration was very intense, thorough and efficient. In a very detailed process, the machine was configured together on site”, summarizes the Heesemannbmanaging director this phase.

In addition to the successful integration into the production line, the MMI package in particular was an important component of the new solution. “We produce fully automated. It is invaluable to see from a distance at a glance what status the machine is in”, explains Martin Eisele, Managing Director of Brunex. So it quickly became clear: An MFA 10 for the line and an MFA impression for the custom production should be. “The ability to configure and adapt the new machines to our exact specifications has ultimately been decisive for our cooperation with Heesemann”, Eisele explains the decision. But also in Bad Oeynhausen they were very satisfied with the cooperation. “Performing a project so thoroughly and in a very trusting relationship at all levels is unusual. But this was the quickest way to find a common solution. All in all, I am very happy with the cooperation”, Giese summarizes. And the opportunity to tour this beautiful spot between the Reuss valley and the Bünztal was certainly very welcome.

Türenfabrik Brunegg AG