From the trade to the industry: Heesemann presents the all-rounder MFA Impression at the LIGNA

Bad Oeynhausen, 03.05.2023

LIGNA at last: As the world’s leading trade fair, LIGNA not only represents the global range of tools, machinery and systems for the woodworking and wood processing industry. Its thematic setting it is also regarded as a driving force for development in the sector. Tens of thousands of visitors from all over the world are expected in Hanover once again from 15-19 May 2023.

Everything changes in May: New hall, new look

Attending the LIGNA has a long tradition at Heesemann. Heesemann has not only been involved since the very beginning but is also celebrating its 90th anniversary this year. Despite this, or perhaps because of it, Heesemann’s participation was met with critical questions. Because the same time, sustainability is also becoming increasingly important for Heesemann.

“The changing conditions in the global economy, the importance of trade fairs but also the issue of sustainability, in particular the search for forms of exchange that take us into a sustainable future, were reasons enough to consider our participation carefully. On the other hand, LIGNA remains the world’s leading trade fair for the wood industry and represents a great opportunity for us to welcome our customers from all over the world. That is why, in the end, we said a clear YES to LIGNA.”

Christoph Giese, Managing Director at Heesemann

In view of this, Heesemann is focusing on a different concept at this year’s LIGNA. Heesemann is relocating to Hall 14, in the immediate vicinity of HOMAG. With just a single machine, the all-rounder MFA Impression plus space for networking, this year clearly focuses on personal interaction with customers and interested parties.

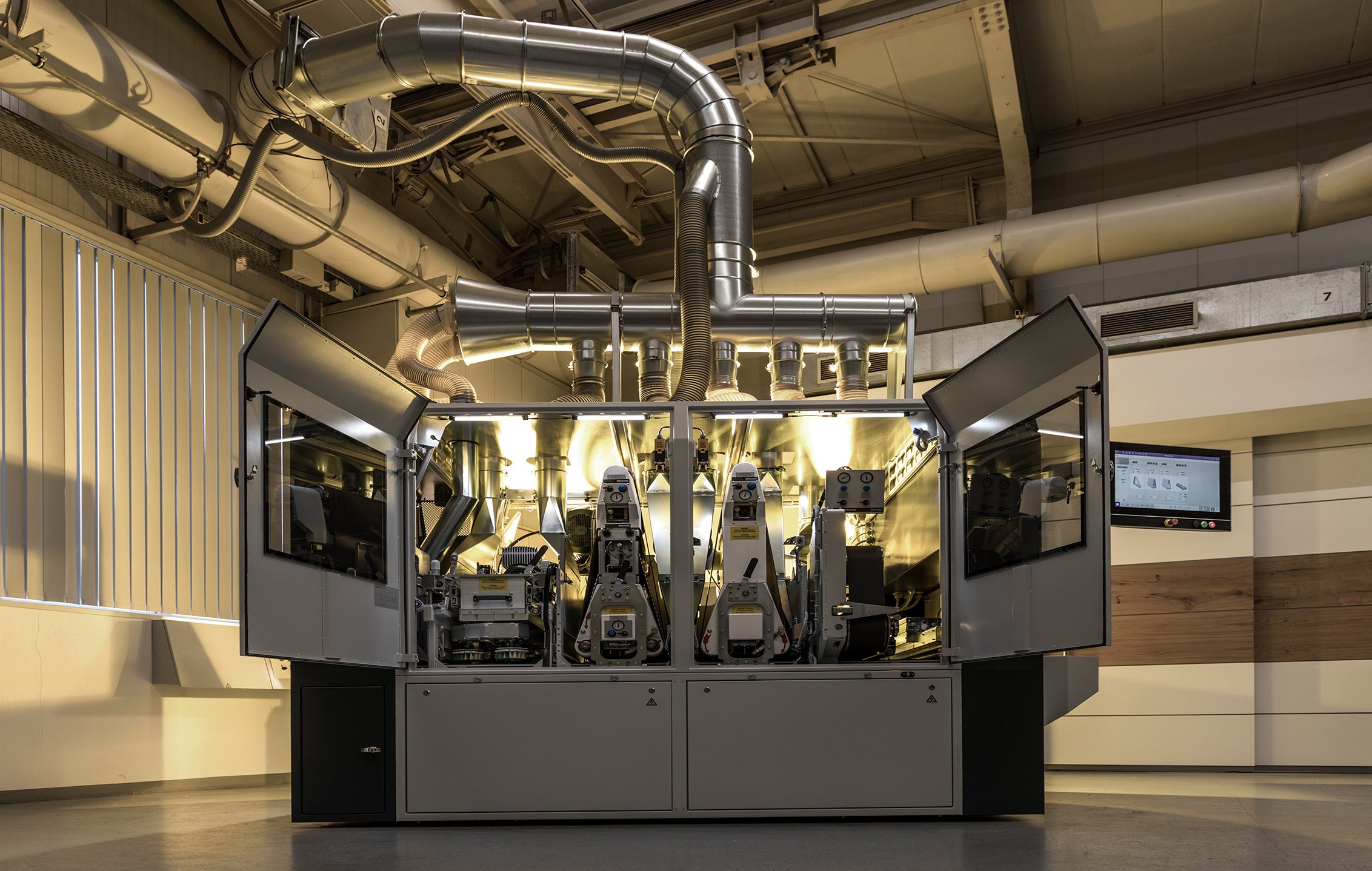

The all-rounder for trades and industry: the MFA Impression

The MFA Impression is the all-rounder for high-end tradespeople. Equipped with a calibrating roller, a longitudinal and cross unit along with the DB-S disc brush unit, it provides the solution for every imaginable sanding job: whether solid wood, veneer, lacquer or 3D surfaces. The MFA Impression is flexible and versatile and appeals to both the tradespeople and industrial companies. This explains why it will be the only machine model on display at Heesemann’s booth. For those who want to see all the machine models, Heesemann is offering a factory tour in nearby Bad Oeynhausen.

Home match: Hanover to Bad Oeynhausen and back

Heesemann’s headquarters are based in Bad Oeynhausen, only a one hour drive from the fair. This is the perfect opportunity to combine a visit to the trade fair with a tour of Heesemann’s plant. Heesemann even offers interested customers a shuttle service to Bad Oeynhausen in the morning, ensuring that they get back to the fair by noon. To take advantage of the shuttle service, simply register online or directly with the booth’s staff beforehand.

Expanded product portfolio: New entry-level models available

Less than a year has passed since Heesemann and HOMAG announced their technology partnership for sanding machines. HOMAG’s declared aim was to continue to cover the customer’s entire process chain. Responsibility for the development and production of sanding machines will remain with Heesemann in the future. Heesemann has now expanded its sanding machine portfolio with three new models to offer universal solutions for every segment from entry-level to high-end solutions. With the SWT-100, HSM Compact and the HSM New Edition, Heesemann now also offers small and mid-sized companies industrial technology at affordable prices. Because all of the machines share one thing in common: All of the models are built around Heesemann DNA. Heesemann makes no compromises when it comes to the quality of the sanded product. Regardless of whether a KSA or an SWT-100 is used, the proven Heesemann quality remains the same.

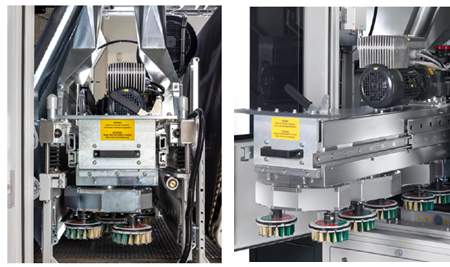

The DB-S disc brush unit delivers perfect sanding without oscillation marks

The DB-S disc brush unit from Heesemann is distinguished by its flexibility and versatility: the unit can effortlessly process three-dimensional surfaces, such as kitchen fronts with fillings or workpieces with curved edges (such as doors, windows, and tabletops) and also create structuring. Another benefit which saves both time and money: sharp workpiece edges are broken during the same pass, eliminating the need for additional manual. So it is no surprise that 9 out of 10 sanding machines delivered are equipped with the DB-S unit.

Karl Heesemann Maschinenfabrik GmbH & Co. KG

Reuterstr. 15, 32547 Bad Oeynhausen

Phone: +49 5731 188-0

www.heesemann.de

Press Contact: Mrs. Cigdem Kurar, c.kurar@heesemann.de