Warranty extension

48 months warranty for your Heesemann ex works – no extra costs!

Heesemann machines are known for their robust construction and durability. Our machines have been in operation for up to 30 years without any significant disruptions. We trust in the good quality of our machines and therefore offer you an extended warranty of up to 48 months. And the good thing about it: no extra costs! You will only be charged for the service calls and wear parts.

Your advantages:

- Protection against unexpected repair costs

- Free repair or replacement in case of warranty

- Maintaining the value of your machine, as the warranty

can be transferred to subsequent owners and is valid worldwide

Requirements:

- For machines built in 2021 or later

- Standard warranty has not expired yet

- Customer service carries out the recommended (chargeable)

service and assembly work every 9 months - Only original is optimal: Use of original Heesemann wear parts, otherwise the warranty will be void

When inspecting your machine, our experienced service technicians will be happy to exchange tips and tricks with you and – if possible – train your operator. Only a well-maintained machine will provide the best possible results over long term. The warranty extension thus offers long-term protection and avoids expensive machine failures.

Contact us: service@heesemann.de

Application advice & technician training

Deepen your knowledge of the technology and exploit its

enormous potential – get the most out of your machine!

Get the best out of your machine by deepening your knowledge of the technology and exploiting its enormous potential.

Content:

- Which unit to use for which application?

- Selecting the right consumables (sanding belts, abrasives,

brushes) - Calibration, structuring, fine and effect sanding

- Creating sanding programs for special applications and

optimal use of the units - Advanced use of the cross sanding method

- Ideal use of sanding units with pressure beams

- Handling of special units (disk brush units, orbital sanding

units) - Avoiding typical sanding mistakes

- Exchange of sanding belts, cleaning of the machine, etc.

Original spare and wear parts

Only original spare and wear parts offer the known quality

and ensure an excellent sanding result – for high machine

availablity and long-term value retention!

Your advantages:

- The combination of powerful units and high-quality brushing

tools ensure excellent processing results - All spare and wear parts fulfi ll the strict requirements on

functionality and lifetime and are produced with respect

to the Heesemann quality standards - Reduce downtimes through high availability of spare

parts, even for older machine series - Bonus program: sales-based bonus will be credited to

your customer account

Bonus program

Benefit by participating in our bonus program for wear and

spare parts – as sales increase, your discount increases!

Your advantages:

- Depending on your sales volume within one year you receive

a graduated bonus that is credited to your customer

account - Only original Heesemann spare parts offer you the quality

you are used to and ensure excellent sanding results - For minimum downtimes and maximum machine availability

- High availability of original spare parts, even for older

machine series

Inspection/ Maintenance agreement

Achieve highest operational safety and optimal sanding

results – get regular maintenace at favorable prices.

Your advantages:

- Our service technicians check your Heesemann once a

year for a flat rate - The flat rate is cleared with realization of the recommended

maintenance and installation work - In addition, you receive 5% loyalty bonus

- Minimized downtimes and increased efficiency

- Preventing damage of the machine

- Cost reduction for service and maintenance

- Highest production safety, maximum machine availability

and long-term value retention - Special units like the DB-S, should be checked on a

regular basis

Machine upgrade

It doesn’t always have to be a new machine. But nobody should notice except you.

Heesemann sanding machines are an investment for eternity. Machines that have been in use by our customers for 30 years or more are not uncommon at Heesemann. Even if they would in principle continue to run for many more years, a “new look” is also good for these machines. But it doesn’t have to be a new machine. Almost new does too: Heesemann Rebuild.

You can check the degree of renewal at Heesemann Rebuild: from the replacement of individual elements, such as the control system, to a complete general overhaul of your Heesemann, everything is possible (feasible for machines built between 1995 and 2012).

Your advantage: You guarantee the production reliability of your machine for many years to come and minimize the risk of a complete breakdown.

For further information on conversion time and costs for your specific machine configuration, our service team is at your disposal: service@heesemann.de

Electrical Rebuild

All control components are exchanged: the control of the

machine, the pressure beam and the operating terminal – for

a machine as new!

Your advantages:

- New user interface for a convenient and intuitive control

- Big touch screen (up to 21.5“)

- More functionalities: extended troubleshooting, video

instructions, maintenance plans, machine documentation

and integrated spare parts catalogue - Effect sanding program (Vintage Look)

- 12 months guarantee on all new control components

Requirements:

- For machines built between 1995-2012

Mechanical Rebuild

The general overhaul is available in three different packages –

all packages include a new control (= electrical Rebuild) and

12 months guarantee for all new components.

Basic package:

- General inspection and thorough cleaning of the machine,

defective and warn components will be replaced

Advanced package:

- All parts in contact with the tools and the workpiece are

also reworked or replaced

„As new“ package:

- The machine will be completely disassembled, cleaned,

painted and equipped with up-to-date components

Requirements

- For machines built between 1995-2012

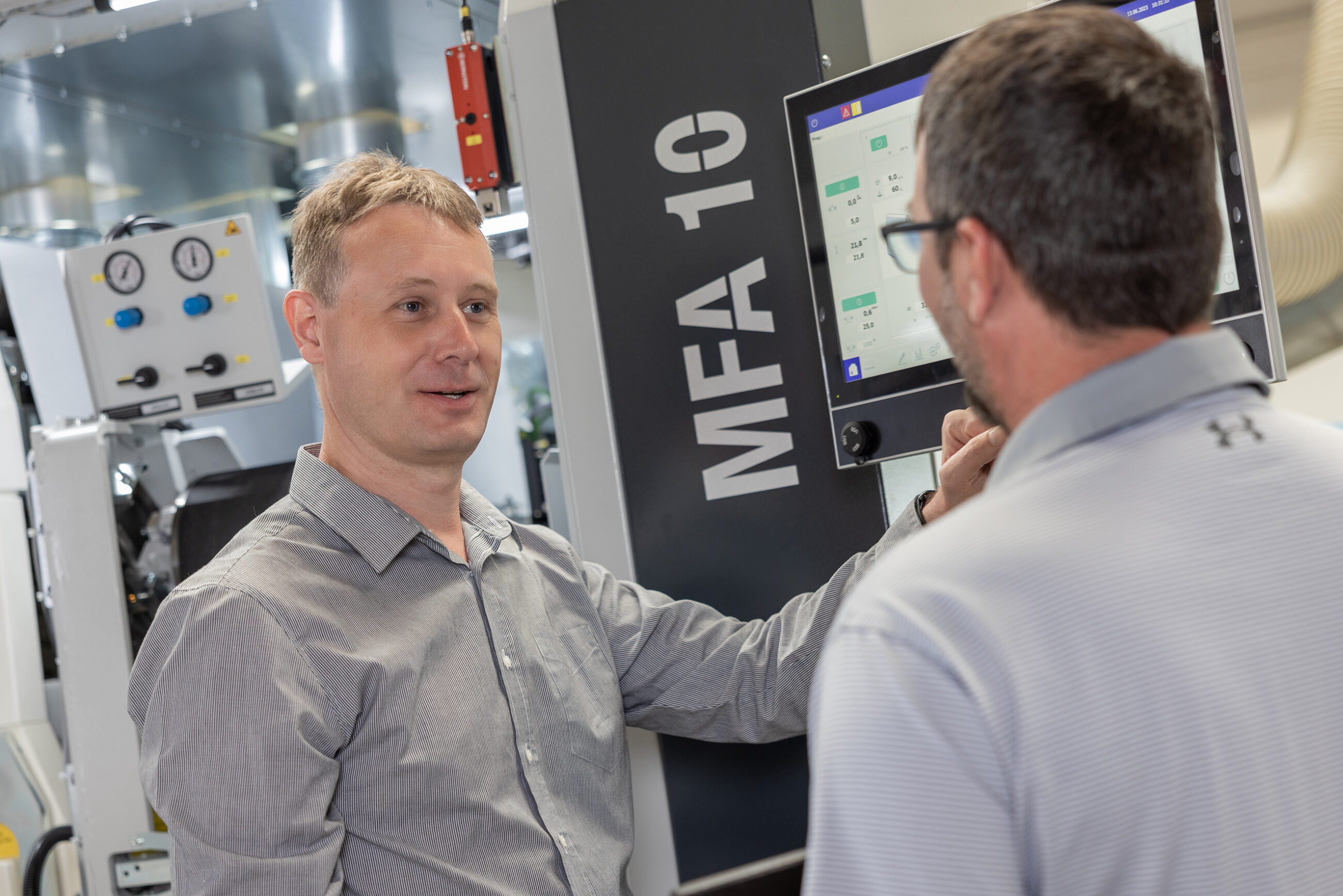

Virtual Service

Virtual Service Solution

System diagnostics and problem solving in real time – service

everytime and everywhere!

Heesemann Virtual Service Solution enables fault diagnosis and problem solving in real time. All you need is a smartphone or tablet. You can use it to send us a live image and, together with our technicians, we will analyze the situation online, identify sources of error and guide you step by step to a solution. Marking on the screen or transmitting documents is easy and immediate. This means that our service staff are available for you at practically any time, minimizing your downtime.

The Heesemann online service package offers another solution. Here, we establish a secure connection with your system and our service expert can see all relevant data from your machine once the connection has been established. This allows them to diagnose processes and intervene in all functions without being on site – even during ongoing production.

Your advantages:

- System diagnostics for machine malfunctions

- Optimization of machine and program parameters

- Minimized downtime and increased efficiency

- Fast problem solving, resulting in higher reliability

- Optimal support for your operating and maintenance

personnel - Cost reduction for service and maintenance

- Software updates, program or function expansions are

carried out online

Intelligent tool management

Optimal use of sanding tools

Your advantages:

- Management of the sanding tools which are in use

- The control system detects the tools which are used and

their condition of wear - Optimum utilization of the service life of the sanding

belts - Safe working: the control recognizes whether the correct

sanding belts are used and if they match the active sanding

program - Cost saving through full utilization of the sanding tools

- More sustainable: there is no waste due to early and

unnecessary changing of sanding belts

Safety-related retrofitting

Retrofit the automatic door locking – occupational safety is

the top priority!

Details & your advantages:

Machine doors may only be opened after the machine has

come to a complete standstill

- Door interlock with standstill monitoring

- Safety flap and modified protective shield on the outlet

- Central shutdown of the pneumatics via software adjustment

- Meet or exceed legal requirements regarding machine

safety

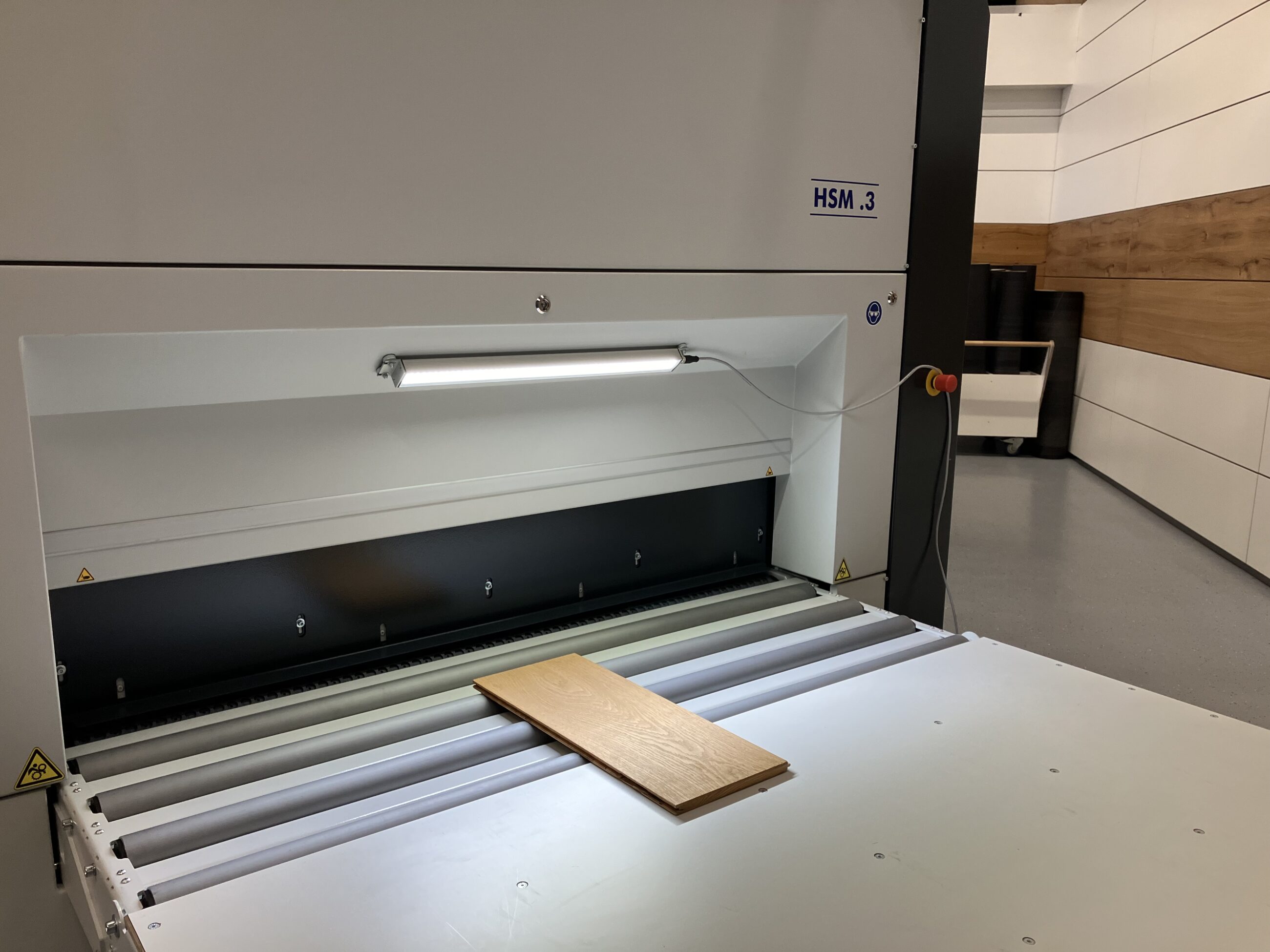

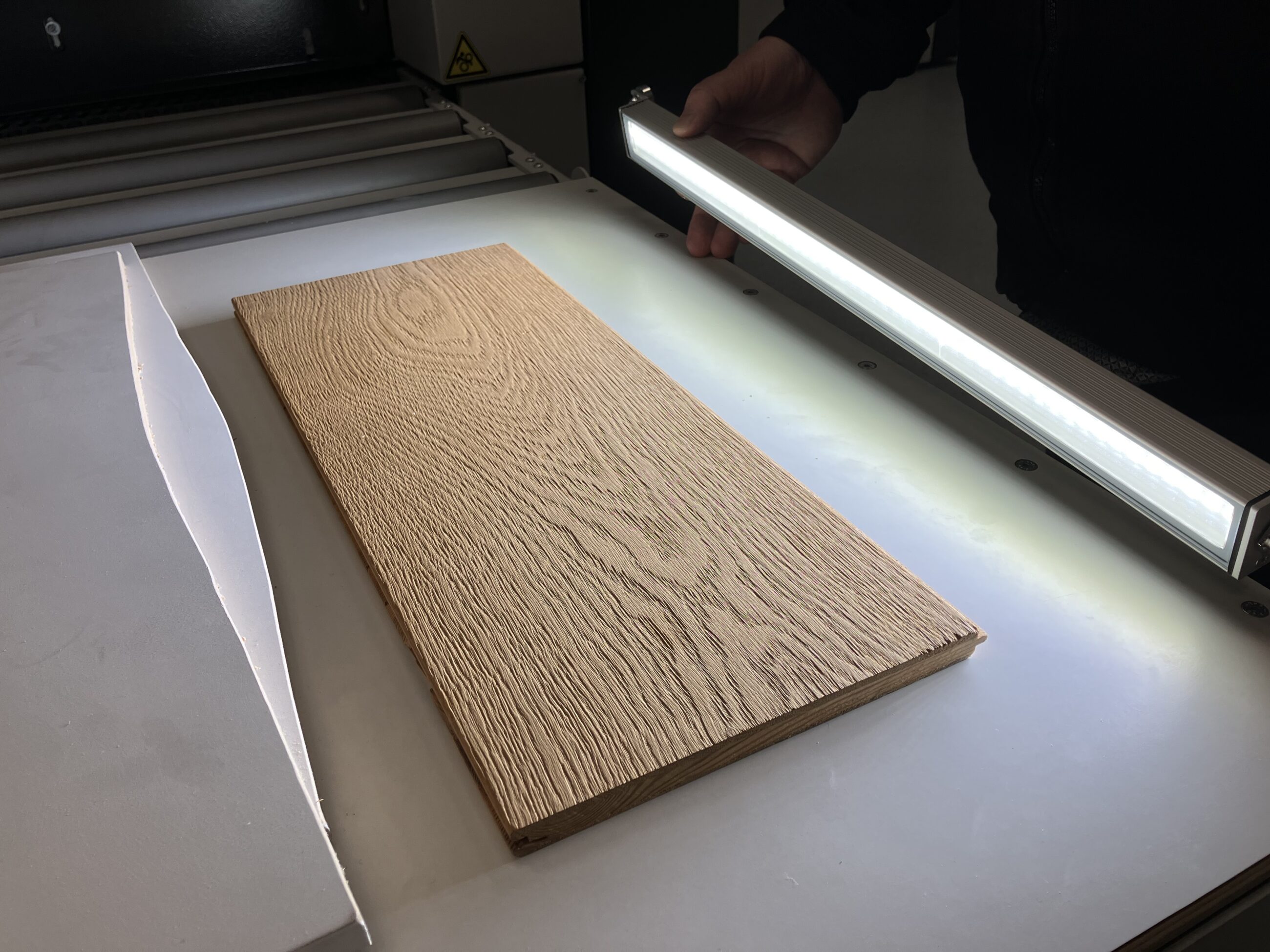

Workpiece inspection light

A practical accessory – the magnetic workpiece inspection

light from Heesemann!

Details:

- The light can be switched on and off in the terminal

- It can be attached to the outlet plate via magnets

- The light can be moved by hand and the workpiece can

be examined - The light can also be attached to the outlet plate so that

the work area behind the machine is illuminated - The light is available for the following machine types:

HSM Compact, HSM New Edition and MFA Impression

(from year of construction 2024)